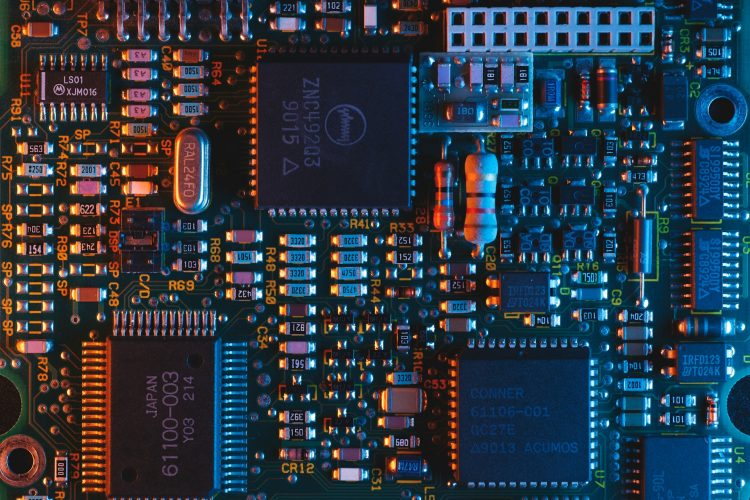

The world of Circuit Board manufacturing is rapidly evolving, driven by advancements in technology and increasing demands for sophisticated electronics. This post explores the intricacies of advanced circuit designs, focusing on rigid-flex PCB, high-frequency, and high-speed PCBs, among others. We aim to provide electronics engineers and PCB designers with a comprehensive overview of cutting-edge PCB solutions and guide them through selecting the best suppliers for their manufacturing needs.

The Landscape of Advanced Circuit PCBs

1. Rigid-Flex PCBs: Combining the Best of Both Worlds Rigid-flex PCBs, a hybrid between rigid and flexible circuits, offer unmatched design flexibility and durability. They are particularly beneficial in applications requiring complex assemblies with space constraints. We’ll delve into the manufacturing considerations, benefits, and typical applications, emphasizing why they’re a favored choice for industries like aerospace and consumer electronics.

2. High-Frequency PCBs: Meeting the Demand for Speed In an era where data transfer rates are critical, high-frequency PCBs stand out. These PCBs are designed to perform exceptionally well at high frequencies, which is essential for applications like telecommunications and advanced computing systems. The post will cover material selection and design principles to maximize performance and minimize signal loss.

3. High-Speed PCBs: Ensuring Integrity in Signal Transmission High-speed PCBs are crucial for maintaining signal integrity in fast data transmission environments. We’ll explore the challenges posed by these designs, such as managing signal integrity and minimizing noise and crosstalk. Additionally, we’ll look at layout techniques and materials that help mitigate these issues.

4. Heavy Copper PCBs: Durability in High Power Applications Heavy copper PCBs, characterized by their thick copper layers, are ideal for high power distribution and heat dissipation. This section will discuss their construction, advantages, and the role they play in industrial and automotive applications, where power density and thermal management are critical.

Selecting the Right PCB Manufacturer

Choosing a Supplier: What to Look For Selecting the right PCB manufacturer is critical to the success of any project involving advanced circuits. Criteria include:

- Expertise and Experience: Manufacturers specializing in advanced PCBs will have the necessary knowledge and experience.

- Quality Certifications: Look for ISO certifications and other quality standards compliance.

- Production Capabilities: Ensure the manufacturer can handle the specific requirements of advanced PCBs, such as layer count, material types, and complexity.

- Reliability and Delivery: Assess the supplier’s track record for on-time delivery and their ability to handle quick turnarounds.

Conclusion

The demand for advanced PCBs is growing as electronics become more integrated into all aspects of modern life. By understanding the different types of advanced circuits and the factors to consider when choosing a manufacturer, electronics engineers and PCB designers can ensure their projects are not only feasible but also successful in today’s competitive market.